Systém PRIMOVE

Technologie VISEON PRIMOVE pro indukční nabíjení ve spolupráci s Bombardier (EN). C 10 naživo v ČR.

Technologie VISEON PRIMOVE pro indukční nabíjení ve spolupráci s Bombardier (EN). C 10 naživo v ČR.

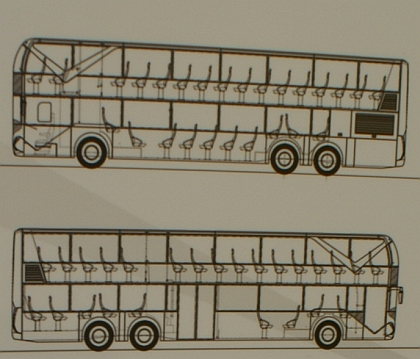

Když prodávala skupina MAN - Neoplan výrobní závod v Pilstingu, málokdo si představoval, že je to impuls pro razantní vznik nové značky. Spíše to asi měla být doplňková výroba menšinových typů jako jsou letištní speciály. Viseon nejenže se pustil do tradiční karosářské výroby, ale brzy představil i futuristický trolejbus. Nyní je možno se seznámit s technologií pro elektrobusy. Tiskovou zprávu uvádíme kompletní v angličtině. Na snímcích představujeme tuto indukční technologii, následně pak detailněji linkový čtrnáctimetrový doubledecker s nízkopodlažní spodní částí a autokar C 10. Končíme záběrem C 10 německého dopravce aktuálně v ČR. Viseon překvapil v nedávné době vstupem společnosti Youngman do firmy. Na tiskové konferenci zástupci Viseonu tazateli vysvětlili, že se vstupem čínského kapitálu ve firmě nic nemění - uvidíme.

VISEON PRIMOVE

In a joint project supported by the Federal Ministry of Transport, Building and Urban Development, VISEON Bus GmbH and Bombardier Transportation are testing new technologies in the area of catenary-free power supply for electrically-powered buses. Under the project name PRIMOVE, Bombardier Transportation has already developed a contactless power supply system for trams which is currently being tested. This new technology should now also be applied in the public service bus sector. As a project partner, VISEON – in its capacity as a trolley bus manufacturer – brings long years of expertise in the development and production of electric-powered buses into the project. "With electric drive technology through the use of overhead lines, we have consistently implemented local emission-free operations for urban buses for many years now," said VISEON´s Technical Director, Ernö Bartha. "With the new catenary-free technology and advanced energy storage systems, this will enable us to eliminate the need for unsightly overhead power lines in towns and cities as well as significantly increasing the flexibility of the electrically-operated public service bus system." At the IAA 2012, Bombardier Transportation and VISEON are presenting the first PRIMOVE public bus which is equipped with a contactless current pick-up on the underside of the floor that has been specially developed by VISEON for use in urban bus operations.PRIMOVE is an electric drive and charging system which is based on the principle of inductive energy transfer. This system has already found use in industry, such as in-plant transportation system, or in homes, e.g. electric toothbrushes. With inductive power transmission, an electrical conductor generates a magnetic field that in turn generates an electric current in another conductor within the field. With the PRIMOVE system, induction loops are installed under the road, for example, at bus stops or on gradients which carries high-frequency alternating current thus creating a magnetic field. A sensor detects whether the vehicle is positioned directly above the loop. Only then does the system activates the re-charging process. In so doing, the magnetic field induces a voltage to the power receiver installed under the vehicle. The system uses this voltage to charge the on-board battery storage or supplies power to the electric drive. For the dynamically-generated power supply during the journey, the induction loops set into the road consist of numerous individual segments. The system activates only that segment over which the vehicle is located. Other road users cannot therefore penetrate the area of the magnetic field.

While the system components installed in the roads passed their baptism of fire in an earlier tram project, the on-board technology -– particularly the power consumption – presented the project partners with major challenges. Unlike trams, buses move on rubber tyres and have soft air suspension. Although this increases the driving comfort for the passengers, it also has the effect that the distance between the vehicle floor – and thus the power pick-up – and the induction loop in the road constantly changes in an undefined manner. VISEON has developed a special lifting and lowering mechanism for extending the pick-ups. This is located underneath the floor of the bus and, if necessary, can be extended downwards in order to reach the magnetic field. For static re-charging, such as bus stops, the power pick-up is placed positioned on the floor to achieve maximum transfer rates. Rollers on the pick-up maintain sufficient distance to the power pick-up and prevents any damage being caused when being lowered. The new, patent-pending lifting and lowering mechanism is designed so that it allows the power pick-up to be re-charged while the vehicle is moving. For static re-charging, the bus drives over charging point, for example, at a bus stop. The system automatically starts the charging process which takes place extremely quickly due to the high level of performance. The driver does not have to intervene in any way. Nor is there any risk of coming in contact with the electricity.

There is another advantage of PRIMOVE as VISEON project manager Christian Vana explained: "For a trolleybus, the electric power lines run from a bipolar network via the pantograph and inverters on the roof to the walls of the passenger compartment and along to the drive in the rear. As there are between 600 to 700 volts here which are directly connected to the grid, this requires a particularly complex insulation process over 3 levels. In a PRIMOVE bus, all the components are already electrically isolated from the mains due to the inductive principle of power consumption. As a result, a high level of safety has already been achieved in the bus through the system and only a simple form of insulation is required as in any other autonomous electric vehicle, such as a battery bus."

Bombardier and VISEON will be testing the technology through to 2013 in order to gather more experience and to try out further development steps.

PR Viseon

BUSportál na veletrhu užitkových vozidel IAA 2012 v Hannoveru

.

Linkový doubledecker LDD 14 © BUSportál

Linkový doubledecker LDD 14 © BUSportál

Linkový doubledecker LDD 14 © BUSportál

Linkový doubledecker LDD 14 © BUSportál

Z tiskové konference © BUSportál

C 10 naživo © (pan)

Linkový doubledecker LDD 14 © BUSportál

Linkový doubledecker LDD 14 © BUSportál

Linkový doubledecker LDD 14 © BUSportál

C 10 © BUSportál

C 10 © BUSportál

BusLine nasadil v České Lípě nové městské autobusy

BusLine nasadil v České Lípě nové městské autobusy

V Ústí nad Labem pokřtili první SORky

V Ústí nad Labem pokřtili první SORky

Jižním Tyrolskem novými autobusy Mercedes a Setra

Jižním Tyrolskem novými autobusy Mercedes a Setra